Mechatronic design services combine mechanical, electrical, and software engineering principles to create intelligent systems that are optimized for performance, reliability, and ease of use. These services are essential for developing innovative products in industries ranging from robotics and automotive to medical devices and consumer electronics. Companies seeking to integrate advanced technologies and smart systems into their products benefit significantly from professional mechatronic design services, which streamline product development, enhance functionality, and ensure higher quality standards.

What is Mechatronic Design?

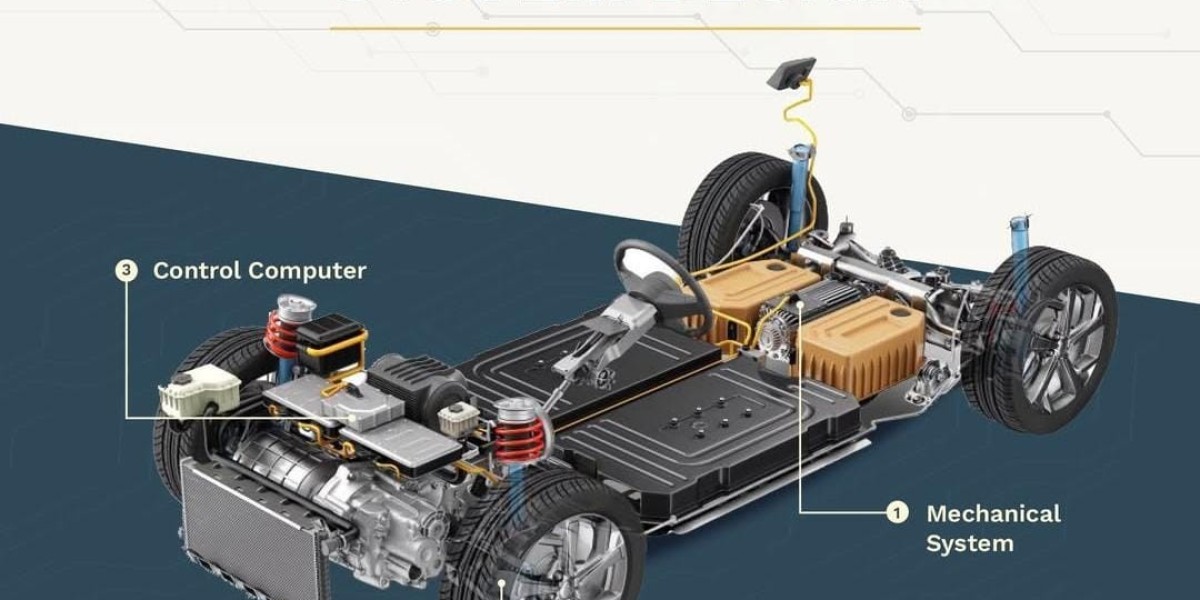

Mechatronic design is an interdisciplinary field that blends mechanical engineering, electrical engineering, computer science, and control engineering. It focuses on designing and developing systems that integrate both hardware and software components to perform a specific task. For example, mechatronic systems are central to devices like autonomous robots, smart manufacturing machines, and advanced medical diagnostic equipment. These systems are often highly complex, requiring careful integration of sensors, actuators, microcontrollers, and sophisticated algorithms to perform intelligently and efficiently.

At its core, mechatronic design optimizes the interaction between the mechanical structure, electrical components, and software systems. This enables the creation of smarter, more efficient, and cost-effective systems that can meet the increasing demands of modern technology.

Key Components of Mechatronic Design Services

Mechatronic design services encompass a wide range of tasks, from initial concept development to prototyping and final product deployment. Some of the key components include:

- Conceptual Design

The first step in mechatronic design is the creation of the concept, which involves identifying the functional requirements and performance criteria of the system. This includes determining the system's size, weight, power consumption, and other critical factors. Engineers work closely with clients to understand their goals and develop a conceptual design that meets these needs while considering technological feasibility, cost-effectiveness, and scalability. - Mechanical Design

The mechanical design phase focuses on the physical structure and dynamics of the system. Engineers design the mechanical components, such as frames, housing, actuators, gears, and linkages, ensuring that they are robust, lightweight, and capable of withstanding the operational environment. Advanced computer-aided design (CAD) software is often used to create 3D models and simulations to test the system's mechanical properties before physical prototyping. - Electrical and Electronics Design

Electrical design is a critical part of mechatronic systems, as it involves creating the electrical circuits and systems that power and control the mechanical components. This includes designing power supplies, motors, sensors, and communication interfaces, as well as integrating these components into the overall system. A focus on efficiency, safety, and reliability is paramount during the electrical design phase. - Control Systems and Software Engineering

The control system is the brain of any mechatronic system. It involves developing algorithms and software to control the behavior of the mechanical and electrical components. Software engineers design the code that enables the system to interact with its environment, process sensor data, make real-time decisions, and execute complex tasks. Whether it's a simple feedback loop or a complex AI-driven system, software engineers create the intelligence that drives the mechatronic system. - Prototyping and Testing

Once the design phase is complete, prototyping is necessary to validate the system's performance and identify any potential issues. Prototypes are developed using rapid prototyping methods such as 3D printing or CNC machining. These prototypes are tested under real-world conditions to evaluate their functionality, durability, and reliability. Engineers iterate on the design based on test results, refining the system to meet performance requirements. - System Integration

System integration involves bringing together all the mechanical, electrical, and software components into a fully functional mechatronic system. This phase requires careful coordination to ensure that the components work seamlessly together, and the system operates as intended. Integration testing ensures that the various parts communicate effectively, and any bugs or issues are addressed before moving on to full-scale production. - Manufacturing Support and Optimization

After the design has been finalized and tested, the manufacturing phase begins. Mechatronic design services extend to providing support for the production process, including selecting materials, optimizing designs for manufacturability, and ensuring quality control. The aim is to ensure that the final product can be produced at scale without sacrificing performance or reliability.

Benefits of Mechatronic Design Services

Mechatronic design services offer numerous benefits for businesses seeking to develop high-performance systems:

- Enhanced Product Functionality

Mechatronic design integrates multiple engineering disciplines, resulting in systems that perform complex tasks with precision. This allows for the development of products that are more functional, efficient, and capable of meeting the needs of end-users. - Cost Efficiency

By optimizing design elements across mechanical, electrical, and software components, mechatronic design helps reduce costs associated with production, maintenance, and energy consumption. Streamlined processes, combined with advanced design techniques, allow for more efficient use of resources and fewer redesigns, which can significantly reduce overall development costs. - Faster Time-to-Market

Professional mechatronic design services help companies bring products to market faster by providing expertise in areas like prototyping, testing, and system integration. By leveraging the experience of skilled engineers, businesses can avoid common pitfalls in product development and move from concept to production more quickly. - Improved Reliability and Safety

A strong emphasis on testing and optimization ensures that mechatronic systems are reliable and safe. Mechatronic design services prioritize durability, safety standards, and quality assurance to deliver products that can withstand real-world conditions without failure. - Innovation and Competitive Advantage

Mechatronic design services enable companies to innovate by integrating cutting-edge technologies, such as robotics, IoT, artificial intelligence, and automation, into their products. These advanced systems can help businesses stay competitive in fast-evolving markets, offering solutions that go beyond traditional mechanical or electrical designs.

Why Choose Servotech’s Mechatronic Design Services?

Servotech offers comprehensive mechatronic design services by servotech that cover the entire product development lifecycle. With a deep understanding of mechatronics and extensive experience across various industries, Servotech helps clients design and develop cutting-edge systems that meet their unique needs. Their team of engineers leverages state-of-the-art tools and techniques to create optimized, high-performance solutions that drive innovation and efficiency.

By partnering with Servotech, businesses gain access to a range of services, from conceptual design and prototyping to manufacturing support and system integration. The company's expertise ensures that every mechatronic system is meticulously designed and tested for optimal performance and reliability, providing a seamless path from idea to finished product.

In conclusion, mechatronic design services are essential for developing the next generation of intelligent, integrated systems. With the right design, businesses can create products that are more efficient, reliable, and innovative. Servotech’s commitment to providing high-quality mechatronic design services helps clients bring their vision to life, with a focus on performance, cost-effectiveness, and cutting-edge technology.