Introduction to PC Hollow Sheets

PC hollow sheets, also known as hollow polycarbonate sheets, are a type of thermoplastic material that has gained significant popularity across various industries due to their lightweight nature and extraordinary strength. Constructed from polycarbonate resin, these sheets are characterized by their unique hollow structure, which contributes to exceptional insulation properties while minimizing weight. Particularly in applications where transparency and durability are paramount, such as in roofing, glazing, and signage, these sheets are revolutionizing how we approach design and architecture. Combining functionality with versatility, Pulkit Plastic Products stands out as a go-to material for engineers, architects, and designers alike.

Manufacturing Process of Hollow Polycarbonate Sheets

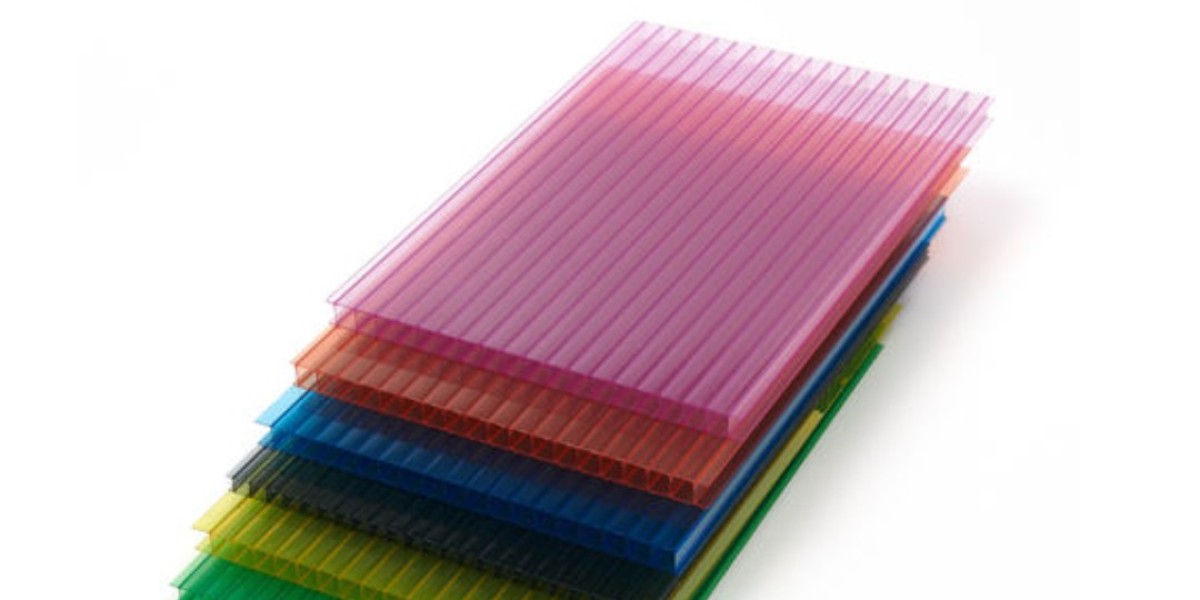

The manufacturing process of hollow polycarbonate sheets begins with the extrusion of polycarbonate resin. The resin, characterized by its high impact resistance and thermal stability, is melted and forced through a die that shapes it into the desired profile, featuring multiple hollow sections. This innovative design reduces the overall weight of the sheet while retaining strength and rigidity. After the extrusion, the sheets undergo cooling and cutting to predetermined sizes, ready for various applications. This process not only ensures uniform quality but also allows for customization in thickness, color, and finish, making hollow polycarbonate sheets suitable for a wide range of projects.

Key Properties and Benefits

The Hollow polycarbonate sheets boast several distinct properties that set them apart from competing materials. One of the most notable features is their high impact resistance—more than 200 times stronger than glass, making them an excellent choice for applications that require durability without sacrificing transparency. Additionally, these sheets offer excellent UV protection, blocking harmful rays that can cause degradation in other materials while providing an optical clarity that rivals glass. Their inherent lightweight quality simplifies transportation and installation, reducing labor costs and shortening project timelines. Furthermore, the thermal insulation properties of hollow sheets can significantly contribute to energy efficiency in buildings, making them an environmentally friendly option in construction.

Applications of Hollow Sheet Polycarbonate

The versatility of hollow sheet polycarbonate has led to its adoption across various sectors. In architecture, it is frequently used for roofing applications, including greenhouses, skylights, and canopies, providing ample natural light while offering protection from the elements. In the signage industry, its excellent light transmission and durability make it ideal for illuminated signage, backlighting, and protective covers. Additionally, hollow polycarbonate sheets are utilized in the automotive sector for components such as headlight covers and internal panels, owing to their lightweight nature and resistance to scratching. The agricultural industry has also embraced this material for its ability to create optimal growing conditions, allowing for the construction of greenhouses that maximize sunlight while protecting plants from harsh weather conditions.

Comparison with Other Materials

When evaluating the use of hollow polycarbonate sheets, it’s essential to compare their properties with those of other traditional materials, such as glass and acrylic. While glass is known for its excellent clarity and aesthetic appeal, it is much heavier and more prone to breakage, requiring more substantial support structures and triggering higher transportation costs. On the other hand, acrylic sheets are lighter and offer good impact resistance, but they are not as robust as polycarbonate in terms of long-term durability and UV resistance. In many applications, hollow polycarbonate sheets emerge as the superior choice, providing a balanced combination of strength, transparency, and insulation in a lightweight package that often comes at a lower overall cost.

Installation and Maintenance Considerations

Installing Hollow sheet polycarbonate is relatively straightforward, but it requires attention to detail to maximize the benefits of the material. Installation guidelines emphasize ensuring proper support and spacing to accommodate thermal expansion and contraction, which is critical for preventing warping or buckling over time. It’s important to utilize appropriate fasteners and sealing methods to protect against water infiltration, particularly in roofing applications. Additionally, when it comes to maintenance, hollow polycarbonate sheets require minimal upkeep, needing only regular cleaning with mild soap and water to maintain their clarity and performance. Avoiding abrasive chemicals and scrubbing pads will prolong the life of the sheets and maintain their aesthetic qualities.

Economic and Environmental Aspects

The economic viability of hollow polycarbonate sheets is underscored by their competitive pricing compared to traditional materials like glass. Their lightweight nature translates to lower shipping costs, while their durability minimizes the need for frequent replacements. Furthermore, when considering environmental impact, polycarbonate is a sustainable choice. The material is 100% recyclable, and its energy-efficient properties can significantly reduce heating and cooling costs in buildings where it is utilized. As more industries shift towards environmentally conscious practices, the adoption of hollow polycarbonate sheets is poised to grow, offering a responsible solution without compromising on performance.

Conclusion

In conclusion, Polycarbonate hollow sheet present a blend of strength, versatility, and economic viability that makes them an invaluable resource across multiple sectors. From architectural applications that utilize their light transmission and insulating capabilities to the signage and automotive industries, the benefits of hollow sheet polycarbonate are far-reaching. As technological advances continue to enhance the performance and sustainability of these materials, designers and builders can rely on hollow polycarbonate for innovative solutions to modern challenges. Its growing acceptance in various industries epitomizes a shift towards materials that not only perform but also appreciate sustainability and efficiency.

Frequently Asked Questions (FAQs)

What are the main advantages of using hollow polycarbonate sheets over glass?

Hollow polycarbonate sheets are significantly more impact-resistant and lightweight than glass, reducing transport costs and improving safety. Additionally, they offer excellent UV protection and thermal insulation properties, making them suitable for a variety of applications where glass might not be ideal.Can hollow polycarbonate sheets be used in extreme weather conditions?

Yes, hollow polycarbonate sheets are engineered to withstand extreme weather conditions, including high winds, heavy rain, and significant temperature fluctuations. Their excellent durability and resistance to UV degradation ensure they remain effective and aesthetically pleasing over time.Are hollow polycarbonate sheets easy to install?

Yes, hollow polycarbonate sheets are relatively easy to install, requiring basic tools and fastening methods. Proper guidelines should be followed for spacing and support to maximize performance and longevity, but the process can generally be completed by individuals with basic construction knowledge.How do I clean and maintain my hollow polycarbonate sheets?

To clean hollow polycarbonate sheets, simply use a solution of mild soap and water with a soft cloth or sponge. Avoid using abrasive cleaners or scouring pads, as these can scratch the surface. Regular cleaning will help maintain clarity and performance while extending the life of the sheets.