A laser engraving machine is a precise tool used across various industries for detailed etching and marking. However, the assumption that it can engrave all materials with the same precision and depth is misleading. Several factors influence how a laser engraving machine interacts with different materials, including laser type, wavelength, power settings, and material properties.

How a Laser Engraving Machine Works

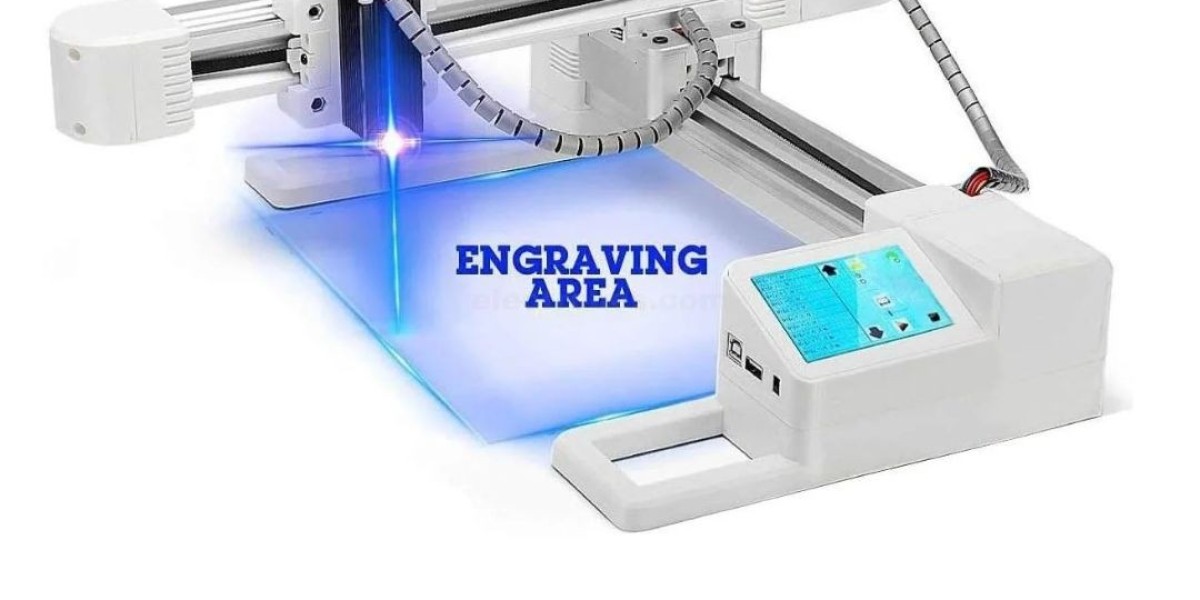

To understand why results vary across materials, it is essential to look at the working principle of a laser engraving machine. This machine directs a concentrated laser beam onto a surface, altering its composition through heat. The interaction between the laser and the material determines whether the engraving is shallow, deep, sharp, or blurry.

Different materials absorb laser energy differently, affecting engraving precision. The three primary laser types used in a laser engraving machine are:

- CO2 Laser: Suitable for engraving wood, acrylic, glass, leather, and some plastics.

- Fiber Laser: Ideal for metals, anodized aluminum, and certain plastics.

- Diode Laser: Works well for wood, leather, and some plastics but struggles with metals.

Since each material reacts uniquely to laser energy, achieving uniform engraving depth and precision across all materials is not possible.

Material-Specific Engraving Considerations

1. Wood

Wood is highly receptive to a laser engraving machine, but different types of wood react differently. Hardwoods like oak and maple require higher power settings than softwoods like pine. The grain pattern also affects the final engraving quality, sometimes causing inconsistencies.

2. Metals

Metals require a fiber laser engraving machine since CO2 lasers are ineffective on uncoated metals. However, even within metals, results vary. Stainless steel engraves well, while aluminum often requires surface treatments for better contrast. Depth precision depends on the material's reflectivity and heat absorption capacity.

3. Glass

Glass is prone to cracking or chipping under high laser intensity. A laser engraving machine must use controlled power settings to create smooth, detailed engravings. Some engraving techniques involve applying masking materials to reduce heat stress.

4. Acrylic and Plastics

Acrylic responds well to a CO2 laser engraving machine, producing clean, frosted engravings. However, different plastics contain varying chemical compositions, leading to inconsistent results. Some plastics may emit toxic fumes when engraved, requiring proper ventilation.

5. Leather

Leather engraves well but requires careful power adjustments to prevent burning or over-darkening. Different leather types react uniquely, with synthetic leather producing fumes due to chemical coatings.

6. Stone and Ceramic

A laser engraving machine can mark stone and ceramic, but the results depend on the surface hardness. Natural stones like marble and granite produce high-contrast engravings, while dense ceramics may require multiple passes to achieve visibility.

7. Paper and Cardboard

Thin materials like paper and cardboard can be engraved, but excessive laser power burns through them instead of etching. Adjusting speed and power settings ensures clean markings without damage.

Factors Affecting Precision and Depth in Laser Engraving

Since no laser engraving machine can engrave all materials with identical precision and depth, several factors must be considered:

1. Laser Power and Speed:

Higher power increases engraving depth, but excessive power may burn or damage delicate materials. Speed adjustments also impact the clarity of engravings.

2. Focus and Lens Type:

Proper focus ensures sharp engravings. Some materials require different lens types to optimize engraving results.

3. Material Density and Composition:

Dense materials absorb laser energy differently, affecting the engraving depth. Reflective surfaces may require specialized coatings to improve absorption.

4. Cooling and Ventilation:

Heat-sensitive materials need cooling mechanisms to prevent damage. Proper ventilation is crucial when engraving plastics or materials that emit fumes.

5. Engraving Techniques:

Different engraving techniques, such as raster engraving and vector engraving, influence how the laser interacts with the material. Raster engraving works well for detailed images, while vector engraving is suited for fine-line work.

Conclusion

A laser engraving machine is a highly versatile tool, but it cannot engrave all materials with the same precision and depth. Factors such as material properties, laser type, power settings, and engraving techniques all play a role in determining the final outcome. Understanding these factors allows users to optimize engraving results for different materials, ensuring high-quality and consistent markings.