Heat exchangers are integral components in various industrial processes, ensuring optimal thermal energy transfer between fluids. Among the diverse types of heat exchangers, the Double Pipe Heat Exchanger stands out due to its simplicity, efficiency, and versatility. Precision Equipment, a leading name in heat exchanger technology, offers high-performance double pipe heat exchangers tailored for diverse industrial needs.

What is a Double Pipe Heat Exchanger?

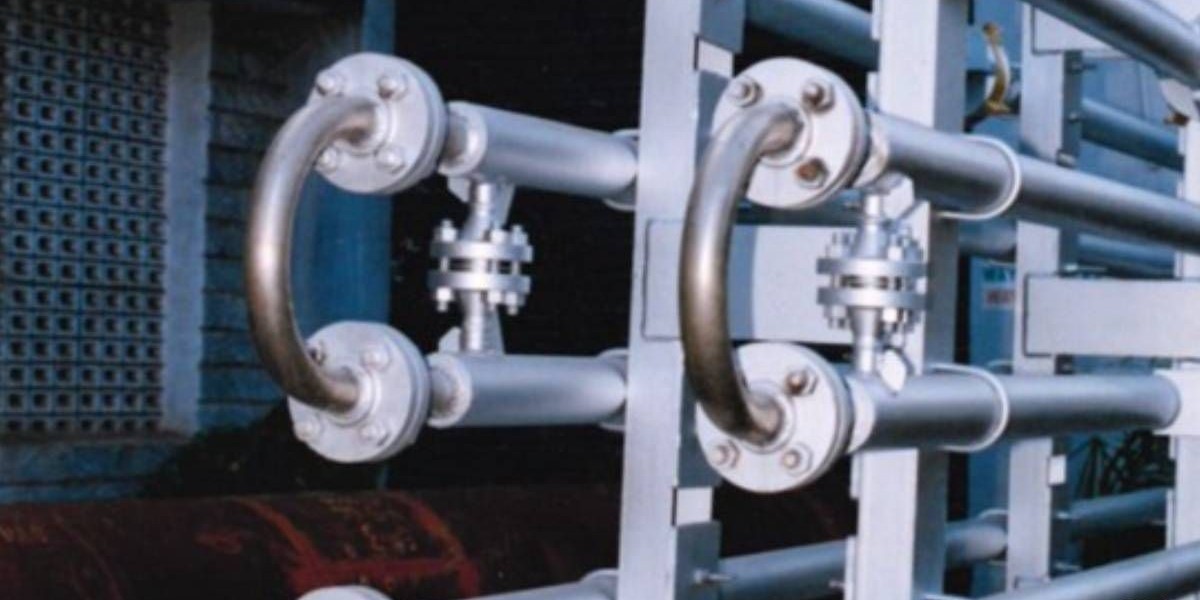

A Double Pipe Heat Exchanger consists of one pipe inside another, facilitating heat transfer between two fluids. One fluid flows through the inner pipe while the other circulates in the annular space between the inner and outer pipes. This setup allows either counterflow or parallel flow configurations, depending on the application’s heat transfer requirements.

Key Components of a Double Pipe Heat Exchanger

- Inner Pipe – Carries the hot or cold fluid for heat transfer.

- Outer Pipe – Encloses the inner pipe, creating an annular space for the second fluid.

- Inlet and Outlet Ports – Enable the controlled entry and exit of fluids.

- Insulation – Prevents heat loss and improves energy efficiency.

How Double Pipe Heat Exchangers Work

The functionality of a Double Pipe Heat Exchanger is straightforward yet highly effective. When hot and cold fluids flow through their respective pipes, heat energy transfers from the hotter fluid to the cooler fluid. This process depends on the heat capacity of the fluids, flow rate, and the temperature gradient between them.

- Parallel Flow Configuration: Both fluids flow in the same direction, resulting in a gradual temperature change.

- Counterflow Configuration: Fluids move in opposite directions, enhancing heat transfer efficiency by maintaining a higher temperature difference.

Precision Equipment designs Double Pipe Heat Exchangers with optimized counterflow configurations to maximize energy efficiency in industrial applications.

Advantages of Using Double Pipe Heat Exchangers

1. Simple and Cost-Effective Design

The straightforward construction of a Double Pipe Heat Exchanger makes it a cost-effective solution for heat transfer applications. Precision Equipment manufactures these exchangers with high-quality materials to ensure durability and long service life.

2. Flexibility in Heat Transfer Applications

Double pipe heat exchangers are highly versatile and can handle various temperature and pressure conditions. Precision Equipment customizes these exchangers based on specific industrial requirements, ensuring optimal performance.

3. Efficient Heat Transfer

Due to the possibility of counterflow operation, a Double Pipe Heat Exchanger achieves higher thermal efficiency compared to parallel flow exchangers. Precision Equipment engineers its heat exchangers with enhanced surface area configurations to maximize heat transfer.

4. Ease of Maintenance

With a modular design, these heat exchangers are easy to clean and maintain. Precision Equipment ensures that its Double Pipe Heat Exchangers are designed for minimal downtime and hassle-free operation.

5. Compact and Space-Saving

These exchangers require less space compared to shell and tube heat exchangers, making them ideal for industries with spatial constraints. Precision Equipment’s compact designs offer high performance without compromising efficiency.

Applications of Double Pipe Heat Exchangers

The Double Pipe Heat Exchanger is widely used across various industries, including:

1. Chemical Processing Industry

Chemical plants rely on heat exchangers for precise temperature control during reactions. Precision Equipment’s heat exchangers are designed to withstand corrosive environments and high-pressure conditions.

2. Oil and Gas Industry

In oil refineries, double pipe heat exchangers are used for preheating crude oil, cooling refined products, and handling process fluids efficiently.

3. Power Generation

Heat exchangers play a crucial role in steam and power plants. Precision Equipment supplies durable heat exchangers that enhance energy recovery and operational efficiency.

4. Food and Beverage Industry

Temperature control is vital in food processing. Precision Equipment provides hygienic and high-efficiency Double Pipe Heat Exchangers to meet stringent industry standards.

5. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems use heat exchangers for effective heat dissipation, ensuring energy-efficient climate control solutions.

Precision Equipment’s Excellence in Heat Exchanger Manufacturing

Precision Equipment is a trusted name in the design and manufacturing of high-performance heat exchangers. With a commitment to innovation and quality, the company provides tailored solutions for industries requiring efficient thermal management systems.

Why Choose Precision Equipment?

- Superior Material Quality: Uses high-grade stainless steel, copper, and other durable materials to ensure longevity.

- Customization: Designs Double Pipe Heat Exchangers to meet specific industrial applications.

- Energy Efficiency: Implements advanced engineering techniques to enhance heat transfer rates.

- Stringent Quality Standards: Ensures each heat exchanger meets international safety and performance standards.

How to Select the Right Double Pipe Heat Exchanger

When choosing a Double Pipe Heat Exchanger, consider the following factors:

- Heat Transfer Requirements – Determine the required heat load and temperature range.

- Material Compatibility – Ensure the materials used are resistant to corrosion and high temperatures.

- Flow Rate and Pressure Conditions – Match the exchanger’s capacity to your process specifications.

- Installation Space – Choose a design that fits within the available space without compromising efficiency.

Precision Equipment provides expert consultation to help industries select the most suitable Double Pipe Heat Exchanger for their applications.

Future Trends in Double Pipe Heat Exchanger Technology

With advancements in materials and thermal engineering, Double Pipe Heat Exchangers are becoming more efficient and environmentally friendly. Precision Equipment is at the forefront of these innovations, integrating smart monitoring systems, enhanced corrosion resistance coatings, and optimized heat transfer surfaces.

1. Smart Monitoring Systems

Real-time monitoring and predictive maintenance systems are being integrated into heat exchangers to enhance performance and longevity.

2. Advanced Coatings

New corrosion-resistant coatings improve durability, especially in harsh industrial environments.

3. Enhanced Heat Transfer Surfaces

Innovations in surface modifications, such as finned and corrugated designs, are boosting thermal efficiency.

Conclusion

The Double Pipe Heat Exchanger is a vital component in various industrial applications, offering superior efficiency, cost-effectiveness, and ease of maintenance. Precision Equipment remains a leader in manufacturing top-tier heat exchangers, providing industries with innovative and reliable thermal management solutions.

For businesses looking to enhance their heat exchange systems, investing in a Double Pipe Heat Exchanger from Precision Equipment ensures optimal performance, durability, and energy efficiency. Whether for chemical processing, power generation, or food industries, Precision Equipment delivers cutting-edge solutions tailored to meet specific industrial needs.