Introduction to ABS Plastic Sheets

Their durability, flexibility, and impact resistance make them a preferred material in various sectors, including automotive, construction, electronics, and consumer goods manufacturing. These sheets are known for their excellent mechanical properties, making them a cost-effective alternative to metals and other rigid materials. Due to their ease of fabrication, they are commonly employed in prototyping and industrial production processes. The growing demand for these sheets has led to an increase in the number of reliable Abs Plastic Sheets Manufacturers In India who cater to both domestic and international markets. These manufacturers ensure the production of high-quality sheets that meet stringent industry standards, providing durable and reliable solutions for numerous applications. Their ability to be thermoformed, machined, and molded into intricate shapes makes them a versatile option for engineering solutions worldwide.

Industrial Applications of High-Quality ABS Plastic Sheets

The use of these sheets extends across multiple industries, owing to their unique set of properties. In the automotive sector, they are widely used for interior and exterior components, including dashboard panels, trims, and protective coverings. Their superior impact resistance ensures enhanced safety and durability in vehicle design. Similarly, in the construction industry, they are employed for wall panels, decorative laminates, and surface protection applications. Their lightweight nature and structural integrity make them a suitable replacement for conventional materials. Reliable Abs Sheet Exporters In Gujarat have expanded their reach to various global markets, supplying quality products that adhere to international standards. This widespread export ensures that industries worldwide benefit from the quality and reliability of these plastic sheets. Other industries such as healthcare, electronics, and packaging also utilize them due to their hygienic properties and resistance to harsh chemicals. The ability to customize these sheets for specific applications makes them an indispensable component in modern manufacturing processes.

Advantages of Using ABS Plastic Sheets in Manufacturing

There are several advantages to using these sheets in various manufacturing processes. Their high tensile strength and excellent toughness make them an ideal material for applications requiring strong impact resistance. Additionally, their lightweight composition allows for easy handling and transportation, reducing production costs in the long run. Another notable benefit is their outstanding thermal stability, allowing them to withstand extreme temperature variations without deforming. As a result, they are used extensively in industries that demand high-performance materials. Leading Abs Sheet 4x8 Manufacturers In India focus on producing standardized sheets that cater to the growing needs of various industries. These sheets are known for their smooth surface finish, making them suitable for applications where aesthetics play a crucial role. Moreover, their excellent machinability ensures that they can be effortlessly cut, drilled, and shaped to meet the specific requirements of different industries. The combination of these properties makes them a preferred choice for diverse engineering applications.

Environmental Impact and Sustainability Factors

With increasing environmental concerns, the sustainability of plastic products has become a critical factor in industrial production. These sheets are considered more sustainable than many other plastic materials due to their recyclability. Many industries are now focusing on utilizing recyclable and eco-friendly materials to reduce waste and promote sustainability. The ability to repurpose and reuse these plastic sheets significantly minimizes their impact on the environment. Several Abs Plastic Sheets Manufacturers In India have adopted eco-friendly production practices to enhance the sustainability of their products. These efforts include reducing plastic waste, optimizing production processes, and utilizing energy-efficient machinery. Additionally, industries are exploring biodegradable alternatives to complement traditional plastic sheets. While these sheets remain a vital part of industrial applications, manufacturers continue to innovate ways to improve their environmental footprint and create a balance between durability and sustainability.

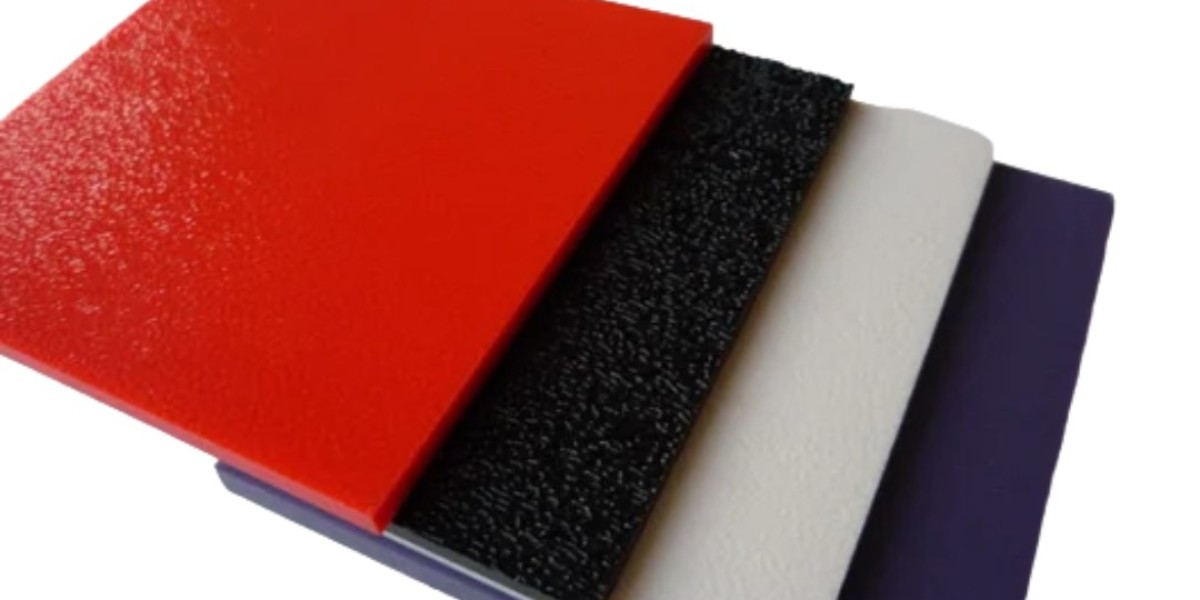

Customization and Design Flexibility of ABS Plastic Sheets

One of the primary reasons these sheets are extensively used in various industries is their customization potential. These sheets can be molded into complex shapes and structures, making them ideal for applications that require specific designs. Their excellent surface finish allows for various finishing techniques, such as painting, laminating, and texturing, to enhance their appearance. Additionally, they can be fabricated in different thicknesses, colors, and patterns to cater to diverse industrial needs. Renowned Abs Sheet Exporters In Gujarat ensure that their products meet the exact specifications of their clients. By offering customized solutions, they cater to industries such as signage, automotive, and interior designing. Their ease of fabrication makes them a preferred choice for prototyping, allowing manufacturers to test and develop innovative products efficiently. This level of customization and adaptability further enhances their usability in different industrial sectors, reinforcing their significance in modern engineering solutions.

Comparing ABS Plastic Sheets with Alternative Materials

When compared to other thermoplastic materials, these sheets offer several advantages that make them a preferred choice in industrial applications. Unlike polycarbonate sheets, they provide a more cost-effective solution while maintaining excellent impact resistance. Compared to PVC sheets, they exhibit superior heat resistance and dimensional stability, making them more suitable for high-temperature environments. The combination of strength, durability, and affordability sets them apart from other plastic materials. Reliable Abs Sheet 4x8 Manufacturers In India produce high-quality sheets that are suitable for demanding applications, ensuring that industries benefit from their enhanced properties. Additionally, their compatibility with various processing methods such as thermoforming, injection molding, and CNC machining makes them more versatile than many alternative materials. This comparative advantage ensures their continued relevance across multiple industries and sectors, making them an indispensable material in modern manufacturing and engineering applications.

Market Demand and Future Prospects of ABS Plastic Sheets

The demand for these sheets has witnessed a steady rise due to their widespread applications in diverse industries. The automotive, construction, electronics, and packaging sectors continue to be major consumers of these sheets. With the rapid expansion of these industries, the need for high-quality and durable materials is also increasing. Manufacturers and exporters in India are continuously investing in advanced production technologies to meet this growing demand. Established Abs Plastic Sheets Manufacturers In India are constantly expanding their production capacities to cater to both domestic and international markets. The global trade of these sheets is expected to increase further, with industries prioritizing reliable and durable materials for their production needs. Technological advancements in plastic manufacturing have also led to the development of enhanced variants that offer improved performance characteristics, reinforcing their importance in industrial applications. The future of these sheets looks promising, with continued growth and innovation shaping the industry landscape.

Conclusion: The Rising Importance of ABS Plastic Sheets

The increasing utilization of these sheets across multiple industries highlights their significance in modern manufacturing. Their unique combination of durability, strength, and versatility ensures their continued demand across various applications. As industries strive for cost-effective and sustainable materials, these plastic sheets remain a reliable choice for manufacturers worldwide. The continuous efforts of Abs Sheet 4x8 Manufacturers In India to provide superior quality products further strengthen their position in the global market. Their adaptability in different industrial applications and their cost-effectiveness compared to alternative materials make them an essential component in engineering and manufacturing. With advancements in production technology and a growing emphasis on sustainability, these plastic sheets will continue to be a vital material for diverse industries, contributing to innovation and efficiency in manufacturing processes.

Frequently Asked Questions

What are the main advantages of using ABS plastic sheets in industrial applications?

These sheets offer excellent impact resistance, high durability, lightweight composition, and superior thermal stability. They are also easy to fabricate and customize, making them suitable for various industries, including automotive, construction, and packaging.

Are ABS plastic sheets environmentally friendly?

While they are made from synthetic polymers, they are recyclable and can be repurposed for various applications. Many manufacturers are adopting eco-friendly practices to minimize waste and enhance sustainability in production processes.

How do ABS plastic sheets compare to polycarbonate and PVC sheets?

These sheets are more affordable than polycarbonate while maintaining strong impact resistance. Compared to PVC sheets, they offer better heat resistance and dimensional stability, making them ideal for high-temperature environments.

Where can I find reliable ABS plastic sheet manufacturers and exporters in India?

Several reputed Abs Plastic Sheets Manufacturers In India and Abs Sheet Exporters In Gujarat supply high-quality products that meet international standards. They offer customized solutions to cater to the specific needs of various industries, ensuring reliable and durable materials for different applications.