Introduction to Uniaxial Geogrids

Uniaxial geogrids are specialized geosynthetic materials designed for soil reinforcement applications. They are characterized by their strength in one direction, making them particularly effective in stabilizing structures such as retaining walls, embankments, and slopes. Uniaxial geogrid exporters in Ahmedabad The unique properties of uniaxial geogrids make them a preferred choice for various civil engineering projects, especially in regions like Ahmedabad, where construction activities are prevalent.

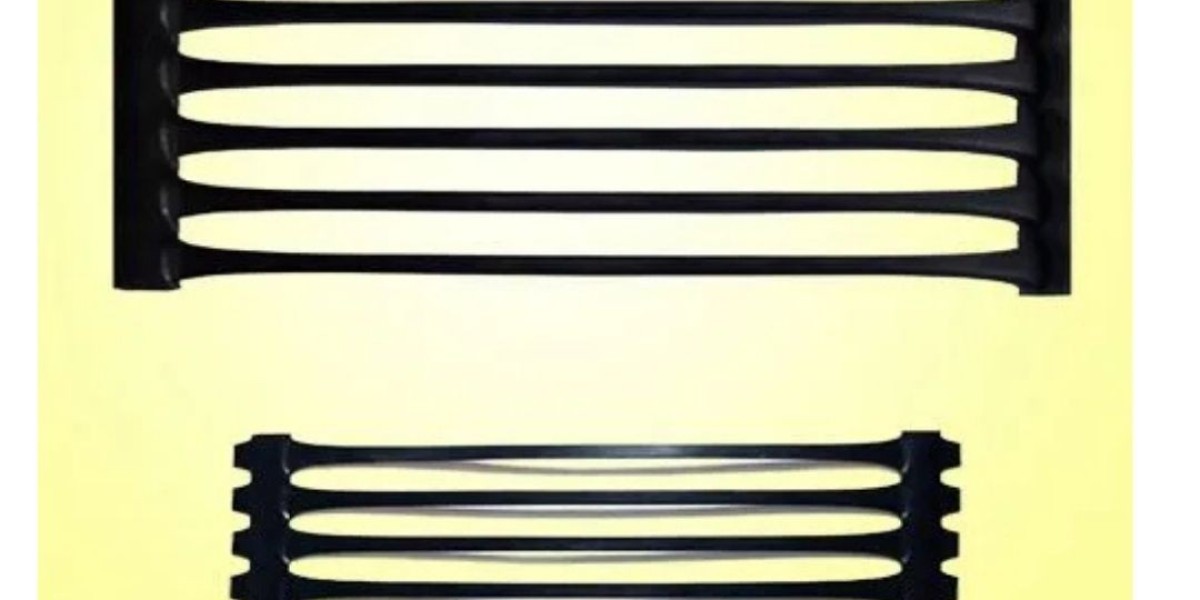

Understanding the Structure and Composition

The structure of uniaxial geogrids consists of long, narrow ribs oriented primarily in the machine direction, which is the direction of maximum strength. Typically made from high-density polyethylene (HDPE) or polypropylene (PP), these geogrids feature apertures that allow soil particles to interlock, enhancing the overall stability of the reinforced soil mass. Uniaxial geogrid manufacturers in Ahmedabad The manufacturing process involves extruding the polymer into a mesh-like structure, which results in a lightweight yet robust product capable of withstanding significant tensile forces.

Applications of Uniaxial Geogrids

Uniaxial geogrids are utilized in various applications, including:

- Retaining Walls: They help stabilize soil and prevent lateral movement, ensuring the structural integrity of retaining walls.

- Embankments: Used to reinforce embankments over soft soils, uniaxial geogrids distribute loads effectively.

- Slope Stabilization: They provide support for steep slopes, reducing the risk of erosion and collapse.

- Landfill Systems: In landfill applications, uniaxial geogrids enhance the stability of liner systems.

These applications highlight the versatility and effectiveness of uniaxial geogrids in modern construction practices.

Benefits of Using Uniaxial Geogrids

The adoption of uniaxial geogrids offers several advantages:

- Cost-Effectiveness: Their simple installation reduces labor costs and excavation needs.

- Environmental Sustainability: Made from recyclable materials, uniaxial geogrids contribute to eco-friendly construction practices.

- Enhanced Load Distribution: They mitigate stress on underlying soil layers, improving overall load-bearing capacity.

- Durability: Uniaxial geogrids resist degradation over time, ensuring long-lasting performance in various environmental conditions.

These benefits make uniaxial geogrids an attractive option for both manufacturers and exporters in Ahmedabad and across India.

Uniaxial Geogrid Manufacturers in Ahmedabad

In Ahmedabad, several manufacturers specialize in producing high-quality uniaxial geogrids. These manufacturers focus on utilizing advanced technology and materials to create products that meet international standards. Uniaxial geogrid exporters in India By investing in research and development, they continually improve the performance characteristics of their geogrids, catering to diverse engineering needs.

Uniaxial Geogrid Exporters in India

India has emerged as a significant player in the global market for uniaxial geogrids. Exporters from India supply these products to various countries, leveraging the country's robust manufacturing capabilities. The combination of quality production and competitive pricing has positioned Indian exporters favorably in international markets.

Comparison with Biaxial Geogrids

While both uniaxial and biaxial geogrids serve essential roles in soil stabilization, their applications differ based on their structural characteristics:

Future Trends in Uniaxial Geogrid Technology

As construction practices evolve, so too does the technology behind uniaxial geogrids. Future trends may include:

- Smart Geosynthetics: Incorporating sensors into geogrid designs to monitor soil conditions and structural integrity.

- Sustainable Materials: Increased use of bio-based polymers to enhance environmental sustainability.

- Advanced Manufacturing Techniques: Utilizing 3D printing technologies to create customized geosynthetic solutions.

These innovations will likely enhance the performance and applicability of uniaxial geogrids in various engineering projects.

Conclusion

Uniaxial geogrids play a crucial role in modern civil engineering by providing effective solutions for soil stabilization and reinforcement. With their unique properties and numerous applications, they have become an essential component in construction projects across India and beyond. As technology advances and demand grows, the future looks promising for both manufacturers and exporters of uniaxial geogrids.

FAQs about Uniaxial Geogrids

What is a uniaxial geogrid?

A uniaxial geogrid is a type of geosynthetic material designed for soil reinforcement that provides strength primarily in one direction. It is commonly used in applications such as retaining walls and embankments.

How do uniaxial geogrids improve soil stability?

Uniaxial geogrids improve soil stability by interlocking with soil particles, distributing loads over a larger area and reducing stress on underlying layers. This helps prevent lateral movement and erosion.

Where can I find uniaxial geogrid manufacturers and exporters in India?

In India, particularly in Ahmedabad, there are several manufacturers and exporters specializing in uniaxial geogrids. These companies focus on producing high-quality products suitable for various civil engineering applications.