Understanding the Significance of Advanced Plastic Solutions

Known for their exceptional durability, impact resistance, and versatile applications, these sheets are favored by professionals and hobbyists alike. Whether utilized in automotive parts, consumer products, or construction projects, their ability to withstand external stress while maintaining their structural integrity makes them a preferred choice. As industries continuously seek durable and cost-effective materials, the prominence of these advanced Abs Plastic Sheet Exporters Ahmedabad solutions continues to grow. They are widely sourced from reputed suppliers to meet the varying demands of industrial and commercial requirements. The growing demand for superior plastic materials has fueled interest in sourcing from reliable vendors to ensure quality and affordability.

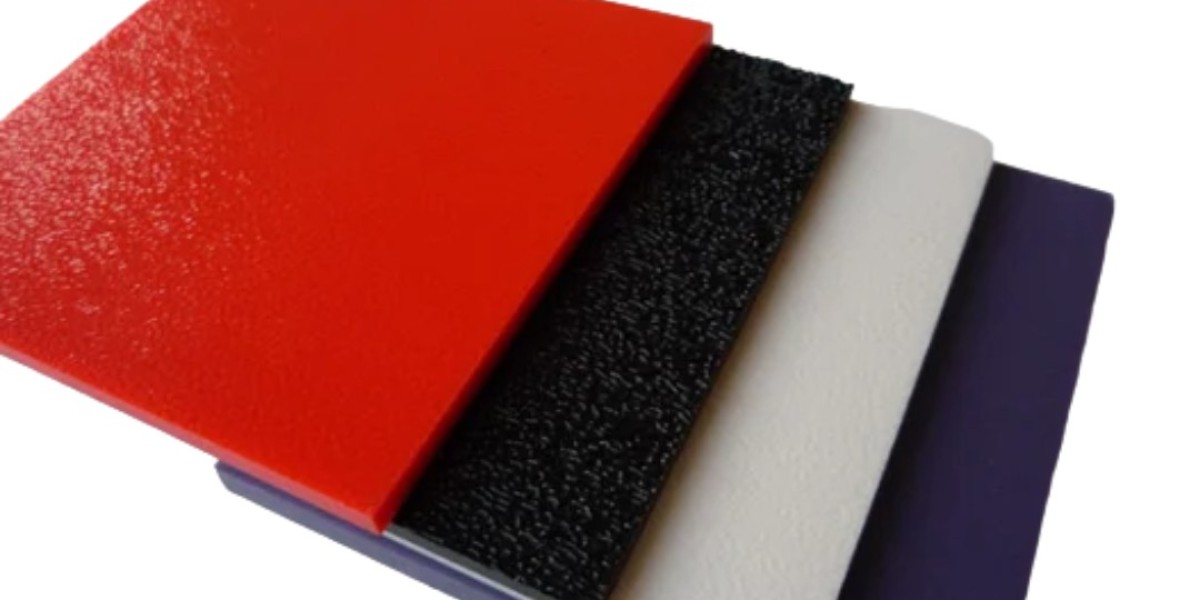

Key Features That Make These Sheets a Preferred Choice

One of the major reasons why these plastic solutions have gained immense popularity is their well-rounded properties. These sheets offer a balance of toughness and rigidity, making them ideal for applications requiring high impact resistance. Unlike other plastic variants, they can be easily thermoformed, allowing them to take different shapes without compromising strength. Additionally, their excellent machinability enables users to cut, drill, and process them into desired structures. The ability to withstand both low and high temperatures without deformation makes them highly reliable in extreme working conditions. Their smooth surface also allows easy printing and painting, further enhancing their utility across different industries. Furthermore, their resistance to chemicals and abrasion ensures that they last longer while maintaining their efficiency in various applications. These properties collectively make them a go-to material for engineers and designers looking for adaptable solutions.

Applications Across Various Sectors and Industries

The versatility of these sheets has led to their widespread adoption across different sectors. The automotive industry extensively utilizes them for manufacturing dashboards, trims, and panels due to their lightweight and impact-resistant nature. In the construction sector, they are frequently used for creating wall claddings, protective barriers, and indoor decorations. Manufacturers of consumer goods rely on them for crafting electronic housings, luggage, and toys. The medical industry also benefits from these sheets due to their hygiene-friendly properties, as they can be easily sanitized without degradation. The growing demand for customization has also led to increased usage in signage and display boards. Architects and interior designers incorporate them into their projects for creating unique and visually appealing elements. Their superior mechanical strength and aesthetic appeal ensure their widespread usability in multiple domains, making them an integral part of industrial innovations.

Understanding the Manufacturing Process and Customization Options

The production of these plastic sheets involves advanced techniques that ensure high quality and uniformity. The process starts with the polymerization of acrylonitrile, butadiene, and styrene to form the base material. This mixture is then heated and extruded into sheets of varying thicknesses. The ability to manufacture these sheets in different dimensions, including the widely preferred 4x8 size, adds to their usability. Precision cutting and molding techniques allow manufacturers to produce sheets that meet industry-specific requirements. Suppliers offer customization options such as textured surfaces, flame retardant properties, and UV-resistant coatings to enhance their functionality. The ability to modify the sheets as per industry needs makes them highly valuable to businesses looking for specialized solutions. Advances in technology have further refined the production process, ensuring that the final product meets global standards of quality and performance.

Factors Influencing Market Demand and Pricing Trends

The increasing dependence on durable plastic solutions has directly impacted the demand and pricing trends. Several factors contribute to market variations, including raw material costs, production efficiency, and supplier network. Manufacturers based in Gujarat play a crucial role in catering to both domestic and international demands, offering competitive pricing without compromising on quality. The availability of bulk supply further ensures that businesses receive cost-effective solutions. In Ahmedabad, pricing dynamics are influenced by factors such as distribution logistics, import/export tariffs, and bulk purchase agreements. While affordability is a key consideration, buyers often prioritize durability and customization features when selecting the right Abs Plastic Sheet 4x8 Manufacturers In Gujarat for their projects. Understanding these pricing factors allows businesses to make informed decisions while ensuring optimal value for their investments. Competitive market conditions also push suppliers to enhance their product quality and offer innovative solutions to attract customers.

Choosing the Right Supplier for Optimal Quality and Reliability

Selecting a trustworthy supplier is crucial for obtaining high-quality plastic sheets that meet industrial standards. Businesses should evaluate vendors based on their manufacturing capabilities, product consistency, and customization options. Leading suppliers in Ahmedabad and Gujarat have established a strong reputation for delivering premium-grade plastic sheets with reliable service support. Checking customer reviews and industry certifications further ensures that the chosen supplier meets quality benchmarks. In addition to product quality, aspects such as timely delivery, bulk order handling, and after-sales support contribute to a seamless procurement process. Partnering with established exporters ensures access to superior products that align with specific industrial needs. Establishing long-term collaborations with reputed manufacturers guarantees a steady supply of durable materials, allowing businesses to streamline their operations effectively.

Sustainable Alternatives and Future Innovations in Plastic Technology

With growing environmental concerns, manufacturers are focusing on developing eco-friendly plastic solutions that minimize waste and enhance sustainability. The recycling potential of these sheets has made them a viable option for businesses looking to reduce their ecological footprint. Advances in biodegradable plastic technology are further shaping the future of this industry. Researchers are actively exploring new formulations that retain the durability of traditional plastic while ensuring reduced environmental impact. The integration of sustainable production methods is expected to revolutionize the plastic industry, offering businesses greener alternatives without compromising performance. Companies investing in responsible manufacturing practices are likely to gain a competitive edge in the market. As awareness around sustainability increases, industries are shifting towards innovative solutions that balance functionality with environmental consciousness.

Conclusion: The Growing Importance of Reliable Plastic Solutions

The increasing reliance on durable and cost-effective materials has solidified the position of advanced Abs Plastic Sheet Price In Ahmedabad across industries. Their ability to withstand challenging conditions while offering flexibility in design and application makes them an invaluable resource. Businesses looking to enhance their operations must consider sourcing from trusted manufacturers and exporters to ensure consistent quality. The evolving market dynamics and technological advancements continue to shape the future of this industry, offering more refined and sustainable alternatives. Whether for large-scale industrial use or custom applications, these sheets remain a preferred choice for those seeking efficiency, durability, and adaptability in their projects. With continuous innovations and sustainability efforts, the future of this industry looks promising, ensuring long-term benefits for manufacturers and end-users alike.

Frequently Asked Questions

What are the key benefits of using these sheets in industrial applications?

These sheets offer exceptional impact resistance, ease of customization, and superior machinability. Their lightweight yet sturdy nature makes them ideal for various industrial applications, including automotive, construction, and consumer goods manufacturing.

How do these plastic sheets compare with other plastic materials?

Compared to other plastic materials, these sheets provide a perfect balance of strength, flexibility, and cost-effectiveness. Their ability to withstand different environmental conditions and their easy processing make them more versatile than traditional plastic options.

What factors should be considered when purchasing these sheets?

Buyers should evaluate factors such as thickness, size, surface texture, and supplier credibility. Additionally, assessing pricing trends and customization options ensures that the purchased product aligns with specific project requirements.

Are these sheets environmentally friendly and recyclable?

Yes, these sheets are recyclable, making them a sustainable choice for businesses looking to minimize environmental impact. Advances in biodegradable plastic technology are further enhancing their eco-friendliness, making them a viable option for long-term use.