Understanding the Unique Properties of ABS Plastic Sheets

These sheets are extensively utilized across various industries due to their durability, lightweight nature, and ability to withstand harsh environmental conditions. The combination of acrylonitrile, butadiene, and styrene in its composition makes it an ideal choice for manufacturers seeking a reliable and cost-effective material. The sheets are easy to mold, cut, and shape, allowing industries to design customized solutions for different applications. Due to its superior mechanical properties, it is preferred over many traditional materials like metal and wood, offering enhanced performance at a competitive price. With advanced manufacturing processes, companies specializing in this material are constantly improving its characteristics to cater to evolving industry demands.

Applications of ABS Sheets in Automotive and Transportation Sectors

One of the primary industries that benefit from these 4x8 Abs Sheet Manufacturers In Gujarat is the automotive and transportation sector. Due to their lightweight nature and high impact resistance, they are used for manufacturing vehicle components such as dashboards, bumpers, door panels, and interior trims. Their resistance to heat and chemicals makes them an excellent choice for applications that require durability and aesthetic appeal. Additionally, the material’s easy machinability and cost-effectiveness allow automobile manufacturers to create complex designs without compromising on performance. Beyond automotive, these sheets are also extensively utilized in public transportation, including railway interiors, bus panels, and aircraft components. Manufacturers specializing in thermoplastic solutions cater to this demand by providing high-quality products tailored for the transportation industry, ensuring safety, reliability, and long-term performance.

Role of ABS Sheets in the Construction and Interior Design Industry

The construction and interior design sectors have embraced the use of these sheets due to their adaptability and aesthetic versatility. Architects and designers use them for wall paneling, partitions, furniture, and decorative applications, where durability and ease of maintenance are crucial. Unlike traditional materials, ABS plastic sheets offer resistance to moisture and corrosion, making them ideal for environments exposed to varying weather conditions. The sheets are available in different textures, finishes, and colors, providing designers with the flexibility to achieve the desired aesthetic while ensuring strength and longevity. Furthermore, due to their insulation properties and fire-retardant capabilities, they are becoming a preferred choice for buildings and commercial establishments requiring high safety standards. Various manufacturers in India are focusing on providing top-quality sheets that meet the specific needs of the construction industry.

The Growing Demand for ABS Sheets in the Electrical and Electronics Industry

The electrical and electronics sector heavily relies on ABS plastic sheets for manufacturing various components due to their excellent insulating properties and resistance to high temperatures. These sheets are commonly used in enclosures for electrical panels, switchgear covers, and protective casings for electronic devices. The material’s lightweight nature and ability to withstand mechanical stress make it an essential choice for electronic manufacturers. Furthermore, ABS is known for its excellent compatibility with different manufacturing processes, including injection molding and thermoforming, allowing manufacturers to produce complex and precise electronic components efficiently. Companies specializing in thermoplastics are actively engaged in supplying high-quality sheets to meet the growing demand in the electronics industry. With the increasing need for advanced electrical safety measures, the adoption of ABS materials is expected to continue expanding in the coming years.

Medical and Healthcare Applications of High-Quality ABS Plastic Sheets

The medical and healthcare industry has also recognized the benefits of using ABS sheets for various applications, including hospital equipment, medical device casings, and furniture. These sheets are preferred due to their non-toxic nature, ease of sterilization, and resistance to bacteria and chemicals. In hospitals and clinics, they are used for protective barriers, instrument panels, and storage units where hygiene and durability are paramount. The ability of these sheets to withstand repeated cleaning and disinfecting procedures without degrading makes them an ideal material for healthcare environments. Moreover, their impact resistance and lightweight characteristics contribute to the development of portable and ergonomic medical equipment. Many leading manufacturers ensure that their products comply with stringent medical standards to provide safe and reliable solutions for healthcare professionals and patients alike.

ABS Plastic Sheets in Industrial and Manufacturing Applications

Industries and manufacturing units leverage these 4x8 Sheet Of Abs Plastic Exporters In Ahmedabad for creating machine guards, workstations, and protective covers. Due to their robustness and resistance to wear and tear, they provide a long-lasting solution for industrial environments where materials are exposed to constant mechanical stress. Many manufacturing facilities use them to develop prototypes and molds due to their easy machinability and precision. In sectors such as robotics and automation, these sheets play a crucial role in developing casings and structural components that require high strength without adding excessive weight. With an increasing focus on innovation, many manufacturers in India are working on enhancing the properties of ABS sheets to meet the evolving needs of the industrial sector. The versatility of this material ensures that it remains a preferred choice for industries seeking durable and cost-effective solutions for various applications.

Why Businesses Choose Reliable Suppliers for High-Quality ABS Sheets

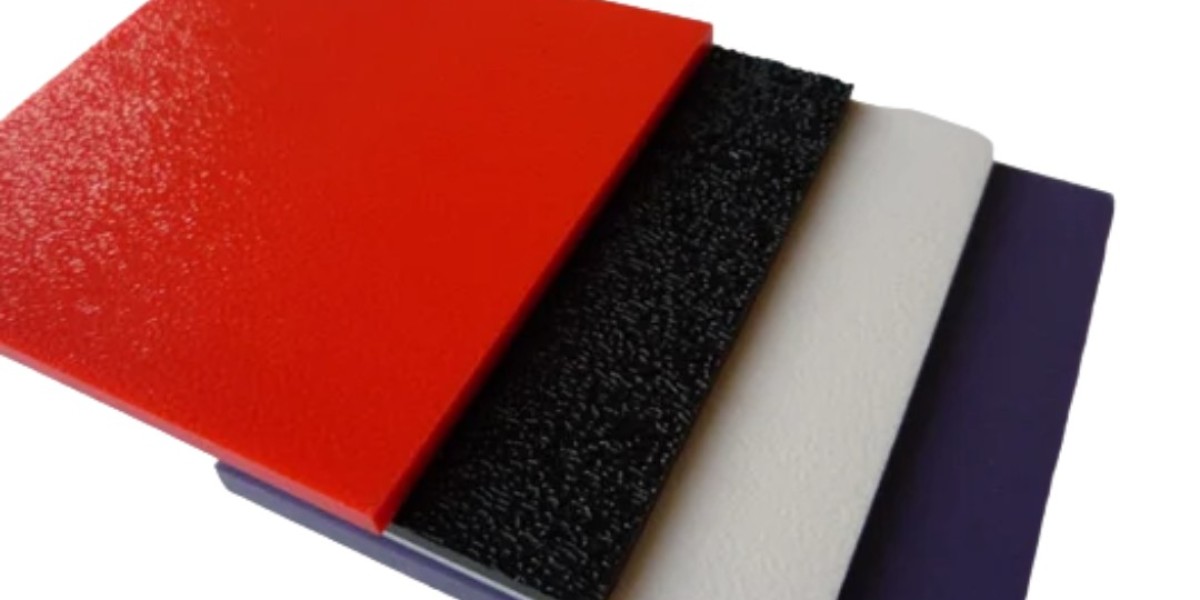

When selecting suppliers for ABS plastic sheets, businesses prioritize quality, reliability, and consistency. A trusted supplier ensures that their products meet industry standards and provide superior mechanical properties for diverse applications. Companies involved in the production and distribution of these sheets must maintain strict quality control to ensure that customers receive durable and high-performance materials. Leading suppliers specialize in providing a range of thicknesses, colors, and textures to meet the specific requirements of different industries. With advancements in technology, manufacturers are also focusing on environmentally friendly production methods to reduce waste and improve sustainability. Businesses looking for premium-grade materials often rely on manufacturers with a proven track record of delivering high-quality solutions. Many reputable manufacturers and exporters in India are playing a crucial role in supplying these essential materials both domestically and internationally.

Conclusion

ABS plastic sheets continue to gain popularity across various industries due to their exceptional mechanical properties, versatility, and cost-effectiveness. From automotive and construction to healthcare and electronics, these sheets provide reliable solutions for countless applications. As the demand for Abs Manufacturers In India materials grows, manufacturers and exporters play a pivotal role in ensuring that businesses receive products that meet their specific needs. With continuous innovations and advancements in material science, ABS sheets will remain a preferred choice for industries seeking durable, lightweight, and customizable solutions. By choosing reputable suppliers, businesses can benefit from high-performance materials that enhance productivity and efficiency in their respective fields.

Frequently Asked Questions

Q1: What makes ABS plastic sheets suitable for automotive applications?

ABS plastic sheets are highly preferred in the automotive sector due to their impact resistance, lightweight nature, and ability to withstand extreme temperatures. Their ease of molding allows manufacturers to create complex vehicle components with high precision, making them an excellent choice for dashboards, bumpers, and interior trims.

Q2: How do ABS sheets contribute to the electronics industry?

The electrical and electronics industry benefits from ABS sheets because of their excellent insulating properties, durability, and resistance to high temperatures. These sheets are commonly used for enclosures, switchgear covers, and protective casings for electronic devices to ensure long-term performance and safety.

Q3: Are ABS sheets safe for medical and healthcare applications?

Yes, ABS plastic sheets are widely used in the medical and healthcare industry due to their non-toxic nature, resistance to chemicals, and ease of sterilization. They are utilized for protective barriers, hospital equipment, and storage units, ensuring hygiene and durability in healthcare environments.

Q4: Why is it important to choose a reliable manufacturer for ABS plastic sheets?

Selecting a trusted manufacturer ensures that businesses receive high-quality, durable, and industry-compliant materials. A reliable supplier provides consistent product quality, customization options, and adherence to safety and environmental standards, making them a preferred choice for diverse industrial applications.