FIBC Jumbo Sling Bags, also known as Sling jumbo bag, are essential tools in the transportation and storage of bulk materials. These bags are designed to handle heavy loads, making them ideal for various industries, including construction, agriculture, and manufacturing. The versatility and strength of these bags stem from their construction materials and design, which allow them to withstand significant weight while maintaining structural integrity.

What is a Sling Jumbo Bag?

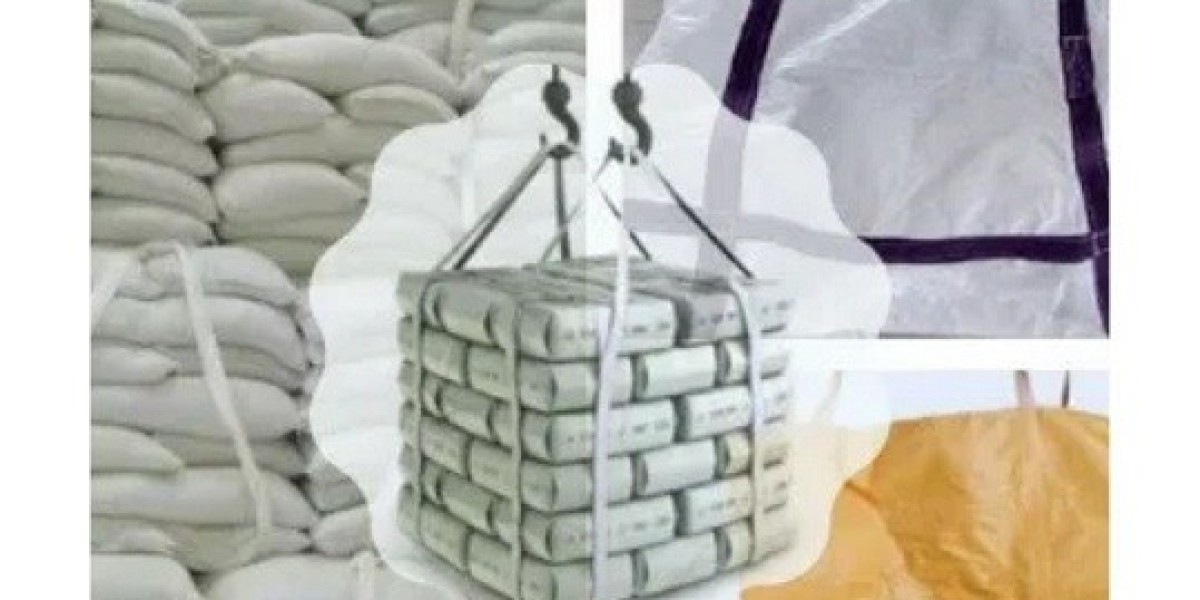

A sling jumbo bag is a type of Flexible Intermediate Bulk Container (FIBC) that features a unique design with lifting loops. These loops allow for easy handling and transportation using forklifts or cranes. Typically made from polypropylene (PP), these bags are lightweight yet robust, providing an effective solution for bulk material handling. The design of a Jumbo sling bag enables it to carry loads ranging from 500 kg to 2000 kg, depending on the specific requirements and construction standards.

Advantages of Using Jumbo Sling Bags

The use of jumbo sling bags offers numerous advantages:

- High Load Capacity: These bags can carry substantial weights, making them suitable for transporting heavy materials like cement, grains, and chemicals.

- Cost-Effective: By reducing the need for multiple smaller bags, businesses can save on packaging costs and improve efficiency.

- Durability: Constructed from high-grade polypropylene, these bags are resistant to wear and tear, ensuring they last through multiple uses.

- Versatility: They can be used for various applications, including storage and transportation of dry bulk goods.

Applications of FIBC Jumbo Sling Bags

FIBC jumbo sling bags are utilized in a wide range of industries due to their adaptability:

- Construction: Ideal for transporting sand, cement, and other building materials.

- Agriculture: Used for storing grains, fertilizers, and seeds.

- Chemical Industry: Suitable for handling powders and granules safely.

- Food Industry: Can be used to transport food grains or other dry food products while adhering to safety standards.

Manufacturing Process of PP Sling Bags

The manufacturing process of PP sling bag involves several key steps:

- Material Selection: High-quality polypropylene is chosen for its strength and durability.

- Weaving: The polypropylene fibers are woven into fabric using advanced techniques to ensure uniformity and strength.

- Cutting and Sewing: The fabric is cut into appropriate sizes and sewn together to form the bag structure.

- Testing: Each bag undergoes rigorous testing to ensure it meets safety and load-bearing specifications.

- Printing (if required): Custom designs or branding can be printed on the bags.

Design Features of FIBC Jumbo Sling Bags

The design of FIBC jumbo sling bags incorporates several features that enhance their functionality:

- Lifting Loops: The presence of loops allows for easy lifting and handling during loading and unloading processes.

- Ventilation Options: Some designs include ventilation features that help in the storage of breathable materials.

- Custom Sizes: Manufacturers can produce bags in various sizes to meet specific customer needs.

Safety Considerations

When using FIBC jumbo sling bags, safety is paramount. Here are some important considerations:

- Weight Limits: Always adhere to the specified weight limit to prevent accidents or bag failure.

- Proper Handling: Use appropriate lifting equipment when moving heavy loads to avoid injuries.

- Storage Conditions: Store the bags in a dry environment away from direct sunlight to prolong their lifespan.

Environmental Impact

As industries become more aware of their environmental footprint, the demand for sustainable packaging solutions has increased. FIBC jumbo sling bags are often made from recyclable materials, making them an eco-friendly choice compared to traditional packaging options. Additionally, their reusable nature contributes to reducing waste in landfills.

Conclusion

In summary, FIBC jumbo sling bags represent a crucial innovation in bulk material handling. Their ability to carry heavy loads efficiently makes them indispensable across various industries. With benefits such as cost-effectiveness, durability, and versatility, these bags continue to gain popularity as a preferred packaging solution. As businesses strive for sustainability, the use of recyclable materials in manufacturing further enhances the appeal of these essential tools in logistics and supply chain management.

Frequently Asked Questions (FAQs)

Q1: What materials are used in manufacturing FIBC jumbo sling bags?

A1: FIBC jumbo sling bags are primarily made from polypropylene (PP), which is known for its strength and durability. Some manufacturers may also use multifilament webbing for added robustness.

Q2: Can FIBC jumbo sling bags be customized?

A2: Yes, many manufacturers offer customization options for FIBC jumbo sling bags, including size variations, printing designs, and additional features based on customer requirements.

Q3: How should I store FIBC jumbo sling bags?

A3: Store FIBC jumbo sling bags in a cool, dry place away from direct sunlight. This helps maintain their structural integrity and extends their usability.