Pressure Seal Globe Valve Manufacturer

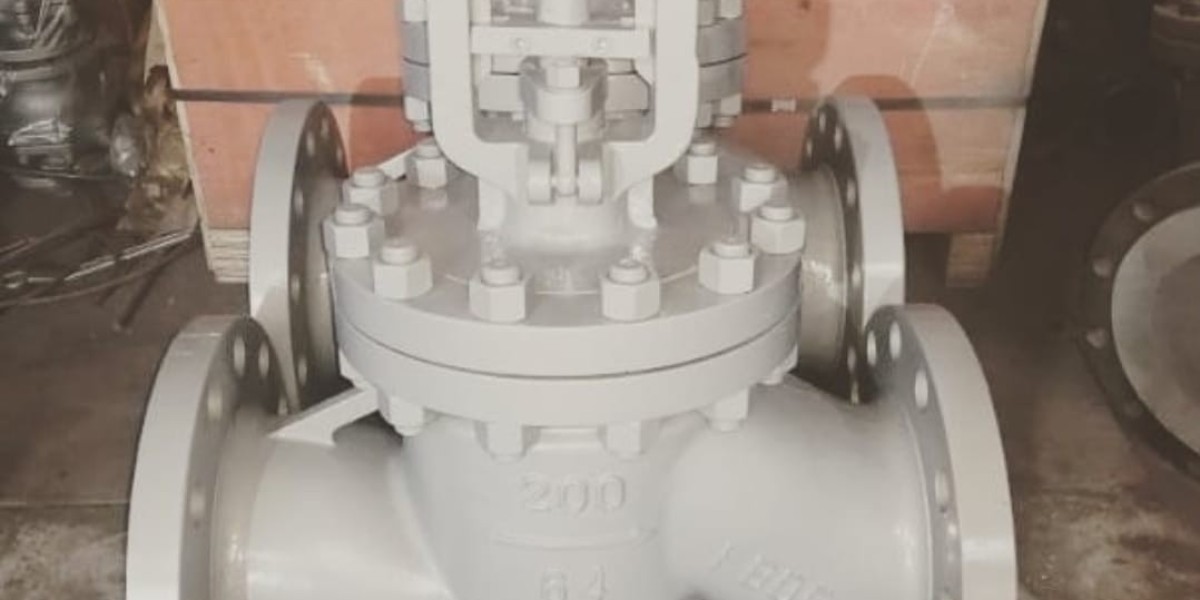

Valvesonly Europe is the best Pressure Seal Globe Valve Manufacturer in Italy. A pressure seal globe valve is a type of industrial valve designed for high-pressure applications, typically found in power plants, petrochemical facilities, and other industries dealing with intense fluid pressures. The primary function of a globe valve is to regulate the flow of fluids within a pipeline. The distinguishing feature of a pressure seal globe valve is its unique design that ensures a tight seal under high-pressure conditions. This valve is characterized by a globe-shaped body with a movable disk (or plug) that can be positioned to control the flow of the fluid.

The working principle of a pressure seal globe valve involves the movement of the disk perpendicular to the direction of flow within the valve. When the valve is open, the disk is lifted away from the valve seat, allowing fluid to pass through. When the valve is closed, the disk is lowered onto the seat, stopping the flow of fluid. The pressure seal design is important for applications where maintaining a secure seal under high pressures is essential. This is accomplished through a different sealing mechanism, which usually involves a combination of pressure applied to the disk and the built-in durability of the materials used in valve construction.

A pressure seal globe valve has a strong, cylindrical body with a spherical top that holds the internal components needed for regulating fluid flow. The valve body is connected to the pipeline, and a stem connected to the disk extends through the valve's top for manual or automatic operation. Pressure seal globe valves are important in industrial operations where protection and reliability are critical due to their tough structure and ability to withstand severe pressures.

Industries-

- Power generation plants

- Oil and gas refineries

- Petrochemical industries

- Chemical processing plants

- Water treatment facilities

- Pulp and paper mills

- Steel manufacturing

- Nuclear power plants

- Aerospace industry

- Shipbuilding

- Mining operations

- Textile manufacturing

- Marine engineering

- Geothermal power plants

- Automotive manufacturing

Parts of a Pressure Seal Globe Valve-

- Body

- Bonnet

- Disk (or Plug)

- Stem

- Valve Seat

- Packing Gland

- Packing Material

- Yoke

Advantages-

- The main advantage of pressure seal globe valves is their ability to handle extremely high pressures. The pressure seal design ensures a tight and reliable seal even under severe operating conditions, making these valves suitable for critical processes in power generation, petrochemical, and refining industries.

- These valves are built with robust and durable materials, such as forged steel or alloy, to withstand the harsh conditions associated with high-pressure environments. This robust construction enhances the longevity and reliability of the valves, reducing the risk of failure and minimizing maintenance requirements.

- The pressure seal design of these valves provides excellent sealing performance, preventing leakage and ensuring the integrity of the system. This is particularly crucial in applications where the escape of fluids could have safety, environmental, or operational consequences.

- Their adaptability makes them suitable for a wide range of applications where high pressures are a constant consideration.

- They offer precise flow control

- They have a long service life

Description:

- Body material: Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

- Class: 150 – 2500; PN10 – PN 450

- Size: DN 10 – DN 1200

- Ends: Butt weld, Flanged, threaded, socket weld

- Operations: Hand-wheel operated, Pneumatic actuated, Electric actuated, Gear operated

Visit us: https://www.valvesonlyeurope.com/product-category/pressure-seal-globe-valve/