Introduction

Haven't you ever been in a ridiculous situation where a tarp that you bought for cheap simply gave up on you in the thick of a storm? Ever wondered this kind of tarpaulin would do a better job protecting your goods, equipment, or space? Exactly the reason PVC vs. Polyethylene Tarpaulin Sheets matter.

Tarpaulins cover absolutely everything, from trucks and boats all the way to temporary shelters, construction sites, and even camping. However, not every tarp is created equally. Choosing the wrong one can mean water leaks, sun damage, and lost money. So, which one actually performs: PVC tarpaulin or Polyethylene tarpaulin?

This article will break down the two materials, their advantages and disadvantages, and the best application for each. You will find out which tarp fits just for you, how to identify quality, and where you may be throwing your money away. When you're done, you'll have a full understanding on how to make a solid choice between these two giants of tarp world.

Understanding Tarpaulin Sheets

What are Tarpaulin Sheets?

Tarpaulin sheets, or tarps as they are commonly referred to, are equivalent to very big, flexible sheets that are made to be waterproof, weather-resistant, and super tough. Really perfect to cover anything well for the elements like rain, wind, UV rays, and dirt. Use of synthetic materials varying for different construction, agriculture, logistics, and even home-usage.

These sheets are available in diverse thicknesses, colors, coatings, and materials according to the intended application. The first things that come to mind regarding tarp materials are the ever-commonly seen Polyvinyl Chloride (PVC) and Polyethylene (PE) in the tarpaulin industry. That's where the battle starts: which is better for your job?

Common Uses of Tarpaulins

Uses of tarpaulins can be multiple. This is how to use them:

- Construction Sites: As scaffolding covers, temporary roof coverings, equipment protection

- Agriculture: Covering hay, or maybe grain or livestock areas

- Transportation: Truck and cargo covers

- Recreational Use: Camping grounds, tents, and shelter solutions

- Home & DIY: Furniture protecting while painting or during renovations

So whether you're a contractor, farmer, truck driver, or just a weekend do-it-yourselfer, you've used a tarp. But have you ever really questioned whether you're using the right one?

What PVC Tarpaulin is?

Composition and Manufacturing Process

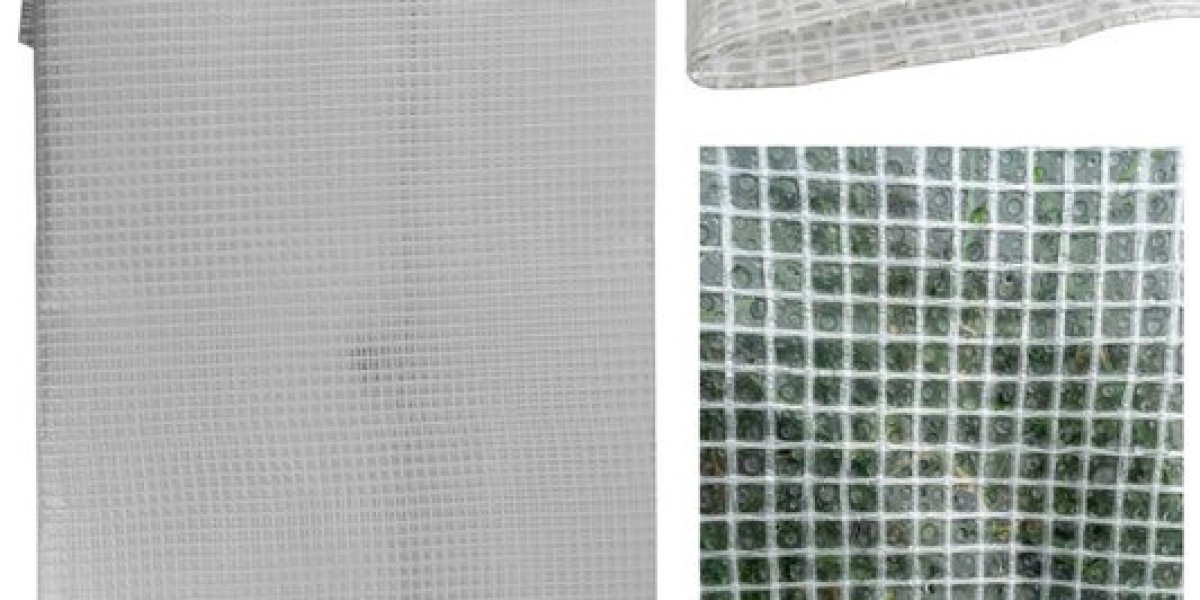

PVC tarpaulin is a type of plastic rubberized material that is flexible, tear-resistant, highly durable, and very much resistant to chemicals and abrasion. It undergoes coating of polyester fabric with PVC resin, forming a very heavy-duty layered product.

This is the reason why PVC tarps are heavy-duty and are tough, and built to last. The tarpaulin usually comprises a polyester scrim, sandwiched between two layers of PVC, which give it great structural integrity. A few of them are also treated with anti-fungal and UV stabilizers to be used in use for quite a long time and in harsh environments.

Characteristics of PVC Tarps

The main asset of PVC tarps is durability. The following are amenities provided by PVC tarps:

- Waterproofing: In respect of dense coating, and close knitting, this would be true

- Chemical Resistance: The material does not give in to oils, grease, and various acids

- UV Protection: Resist being cracked or destroyed in the sun as opposed to cheaper materials

- Flame Retardant: Many of these tarps are inherently resistant to fire

- Surface Finish: Below, even after being easily scratched while used

- Thickness: Based on personal choice from 400 GSM to 900 GSM

Given these particularities, tariffs for PVC legs are mainly utilized in the industrial arena where reliability is not just a goal. However, with power shall come a price. Additionally, they are heavier and usually less expensive than the tariffs for the former PE.

What Is Polyethylene Tarpaulin?

Structure and Fabrication

Polyethylene is mainly built from woven low-cost plastic tape, then a coating of plastic is laminated over the woven fabric. This procedure is essentially cheaper and archaical compared to PVC-producing structure, among other things the reason why PE is taking over in budget tarp market.

Often the raw materials will vary from LDP for flexibility to HDP for better strength. These tarps are available in different grades, which range from light economy through mid-grade to heavy duty.

Primary Features of PE tarps

Despite their lower strength, there are many advantages associated with polyethylene covers:

- Easy and Lightweight: Even a school kid can carry it; they fold, install, and come down easily

- Pocket-Friendly Option: Definitely cheap when compared to PVC tarps

- Waterproof and UV Resistant: Short-term or medium-term use is fine too

- Numerous Colors, Sizes: From small blue tarps to multilayered large sheets

- Reusability: Lots of PE material is constituted from recycled plastics

People employ PE coverages to protect for miscellany of usages such as covering garden equipment, camping necessities, temporary shelters, etc. But most often, longer exposure to sun or strenuous conditions can tend to mar their durability.

A Comparative Study about PVC and PE Tarpaulin

Durability and Strength

Heavy Duty Tarpaulin PVC comes on top when it comes to durability, offering a very good time under rough handling, environmental stress, and long-term exposure. Due to its polyester and PVC layers, puncture, abrasion, and tearing resistance are greater than polyethylene plastics.

PE, the light-duty champion, comes very tough yet still degrades quickly, especially under heavy loaders or long exposure. They are the very best for short-term or light duty work, but if you're going to invest into something that lasts a season if not a year, very well then, that is laboring under a lost cause.

At the other end, PVC as a material would last for years in favorable conditions; hence, it is a material for industrial-type sites, long-haul transport covers, and permanent outdoor shelters. It's one of those tarpaulins you set up and basically forget about; until a year of sunlight later you realize, wow, this tarp is still standing!

Flexibility And Handling

Here's where polyethylene gets appreciation. PE tarps are way lighter, thus easier to fold, transport, or handle. Whether it's something you toss over your firewood pile or to cover up a leaking roof, polyethylene is manageable: easy even for one person to handle.

PVC is bulkier and heavier, but it can be quite flexible too with some temperamental qualifications. More often than not, weather determines how flexible PVC is. It feels flexible on a sunny day or even in warm conditions. But if it's freezing cold in your neck of the woods, doing anything with PVC becomes a real struggle. This feature can do nothing for you when you're in a cold climate and flexibility and ease of setup for heavy-duty projects are your main priorities.

Therefore, PE is better for occasional use and for jobs that include a lot of moving and folding. For jobs that include a permanent setup or where wind and weather demand a heavier alternative, PVC is your best bet.

Weather And UV Resistance

Both these tarpaulins may be weatherproof, but there is an enormous difference in their protection abilities. PVC tarps win the waterproof battle and are generally treated for UV, mold, and mildew resistance. They can take indefinite exposure to sunlight without fading and won't get brittle under such conditions, thus, are good for covering roofs, awnings, or tents in outdoor events.

Typically, PE tarps in the market do UV treatments, though they eventually wear off. After strong sun exposure for a few months, you would see extensive wear on it: fading, developing brittleness, and sometimes even tearing. They also won't perform as well during windy weather when grommets get ripped out because of the stress.

Bottom line: do go with PVC if you want long-lasting UV protection and heavy-duty resistance to extreme weather. Use PE to cover something short-term—just keep it out of that overheated sun for too long.

Weight and Portability

In terms of weight, polyethylene tarpaulin is lighter by a long shot. A nice-sized PE tarp is great for any camping or hiking event or even DIY garden use—it is easy to carry. Fold it up, roll it up, and toss it in one' s backpack without breaking a sweat.

A PVC tarp, because of its denser material and thicker coatings, is, however, heavier. Therefore it cannot be relied upon much for mobile applications. One person usually needs help or sometimes even equipment to transport and set up larger PVC tarps.

But, that added weight provides stability. In windy or storm-prone environments, those extra pounds serve as glue, anchoring the tarp to its held positions and preventing it from wildly flapping.

Cost Efficiency

This is where dollars and cents come into play. PE tarp is way cheaper than PVC. A good-sized polyethylene tarp is just a tiny fraction of the price of a similar-sized PVC tarp. For temporary jobs, PE is the go-to product of choice for most cost-conscious clients.

However, as would be apparent, PVC tarps have a longer lifespan, so the cost of replacement is much less frequent, hence the upfront cost is actually quite high. In such cases, if you buy tarps every season for usage, an investment in PVC should actually save you money in future.

Here is the above: Yes, polyethylene becomes king when you need it for the short-lived afford abilities, but PVC comes as your best friend in long-term cost-effectiveness.

Applications and Industry Preference

When to Use PVC Tarpaulin

PVC tarpaulins likewise find their place in harsh environment applications. They are used in:

- Construction: covering and shielding scaffolding, machinery, and temporary workplaces

- Transport: providing covers for trucks conveying cargo, especially in long hauls

- Farming: greenhouse covers, water harvesting systems

- Events: marquee tents, stages, and outdoor exhibits

- Storage in Industry: long-term materials protection

Most of these scenarios call for durability, resistance to water, and integrity in structure - all of which PVC can provide consistently. It is really the only thing for the professionals out in harsh conditions.

When to Use Polyethylene Instead

Polyethylene is for light to medium-duty uses such as:

- Camping trips and hiking for quick shelters or ground sheets

- Covering furniture during home renovations

- Protecting firewood or garden equipment

- Short-term roofing or leak patching

- Temporary setting up for events, such as a festival or school function

Whereas weight, cost, and ease of handling trump over time, PE was the better choice.